Creation of safe working conditions

Occupational health and safety management

Samruk-Energy JSC provides safe working conditions for employees and contractors, strictly complying with the legislation of the Republic of Kazakhstan and is guided by the recommendations of ISO 45001 international standard, which is confirmed by regular audits.

HSE objectives of Samruk-Energy JSC:

- improving the efficiency of business processes through continuous development of the corporate management system;

- compliance with all applicable health and safety regulations and requirements defined by legislation and international standards;

- guaranteeing safe and comfortable working conditions, reducing risks to the health of personnel and all stakeholders by preventing and eliminating possible hazards;

- application of modern equipment, innovative technologies and protection means to ensure workplace safety;

- organising consultation with employees and ensuring their active participation in health and safety processes.

In the reporting period, we continued to work on improving labour safety and adapting our strategy to new conditions. As part of this, we have developed a Zero Injury Plan, including:

- Visualisation of briefings (slides/video) and testing of employee knowledge.

- Proactive measures: behavioural audits, registration and investigation of dangerous situations (Near Miss), right to suspend work, collective responsibility for health and safety violations.

To maintain and improve the level of safety at production facilities, Samruk-Energy JSC systematically invests significant resources in the implementation of HSE measures.

Financing of HSE measures, KZT billion

| 2022 | 2023 | 2024 |

|---|---|---|

| 3.789 | 2.995 | 4.648 |

The main cost items include costs of laboratory tests, protective clothing and personal and collective protective equipment, costs of providing milk and other food products, medical examinations, minimisation of injury risks (introduction and/or modernisation of technical devices), etc.

Company HSE regulatory documents

The labour protection and industrial safety management system in Samruk-Energy JSC covers all employees of the company and contractors. It is based on the legislation of the Republic of Kazakhstan, internal corporate standards and safety principles. The regulatory framework of Samruk- Energy JSC in the field of labour protection and industrial safety includes a set of documents developed in accordance with the legislation of the Republic of Kazakhstan, international standards and internal corporate regulations.

To encourage and engage personnel in OHS programs, individual initiatives aimed at improving workplace safety are supported and encouraged. At Samruk-Energy JSC, a monetary incentive/reward program has been implemented based on the "Employee Motivation for Safe Behavior" standard. Through this program, employees can report hazards and dangerous work-related situations.

Safe working conditions are being created: repair works have been carried out in shower rooms, modular toilets and drinking fountains have been installed. Employees are provided with all necessary personal protective equipment.

- Corporate Governance System Policy of the Samruk-Energy JSC Group of companies;

- Regulations on Transportation Safety Management in the Group of companies of Samruk-Energy JSC;

- Regulations on prevention and improvement of employees' health;

- Regulation on the organization of work of contractors in the Group of companies of Samruk-Energy JSC;

- Strategy for the H&S Development (2024–2028);

- Occupational Health and Safety Risk Assessment Standard;

- Motivation of Personnel for Safe Behavior Standard;

- Accounting and Investigation of Accidents Standard;

- Assessment of Industrial Safety and Labor Protection Risks Standard.

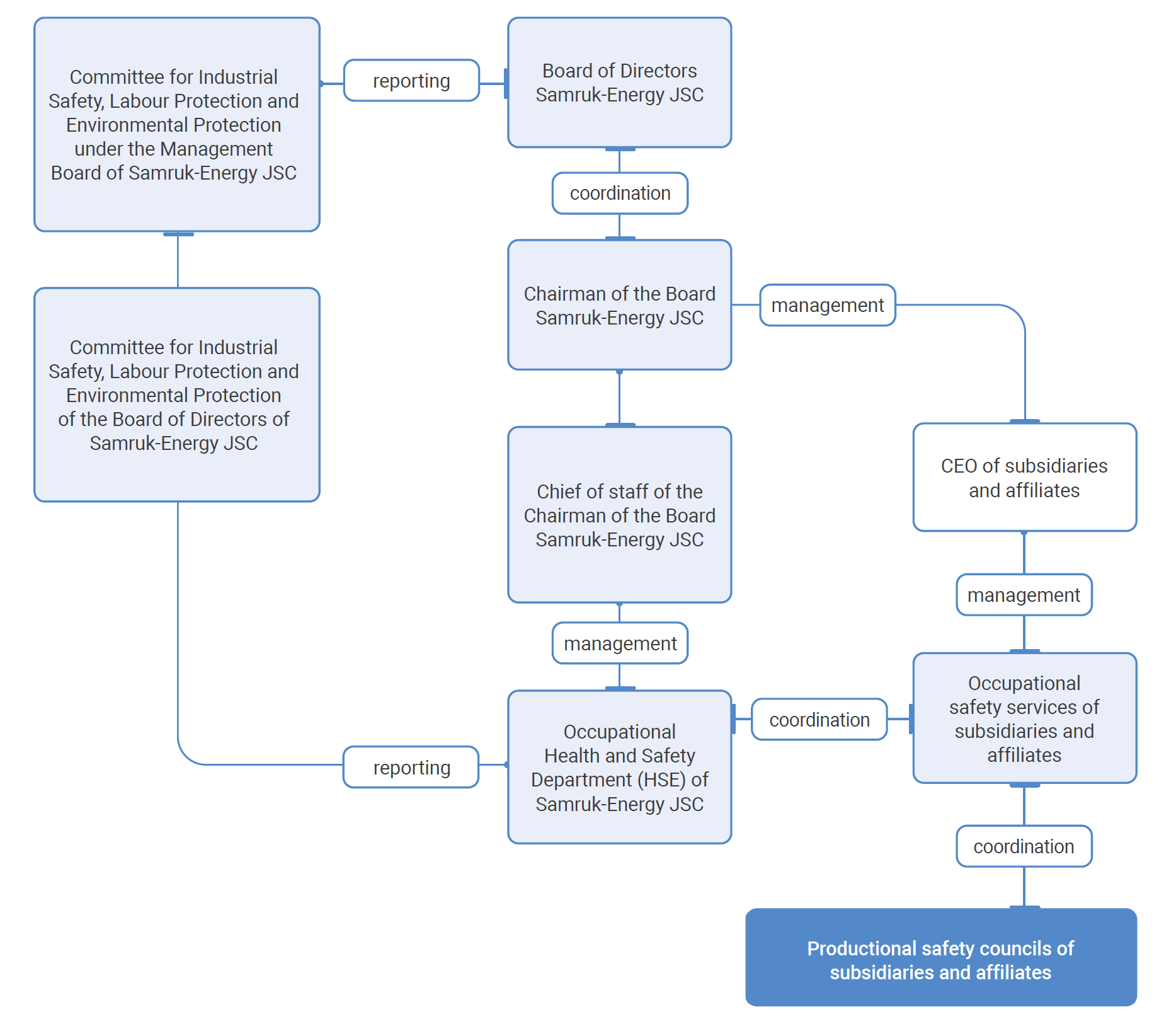

HSE management structure

The Company manages occupational health and safety at all levels.

The Occupational Safety Service includes 6 specialists in the central office, of which 4 are responsible for labour safety, 1 for industrial safety and 1 for fire safety. Subsidiaries employ 85 specialists: 40 for occupational safety, 23 for industrial safety and 11 for fire safety. The entire labour safety system covers 17,898 employees who have undergone internal audits, and the ratio of safety specialists to the total number of employees is 1:200.

Safety issues are coordinated by the HSE Director, who reports to the Chairman of the Management Board and oversees the implementation of measures to improve the occupational safety system in the Company and subsidiaries and affiliates. The head of the HSE division is responsible for preventing violations, responding to incidents, monitoring and analysing risks. In subsidiaries, the occupational safety services report to the first managers, and their qualifications are regularly reviewed to improve efficiency.

Monthly meetings are held with the Chairman of the Management Board, Chief Directors and heads of subsidiaries to improve safety culture and reduce injuries. Occupational Health and Safety Committees analyse the safety status and monitor the implementation of measures. In 2024, 5 meetings of the committees and 48 meetings of production councils were held with the participation of employer representatives and technical inspectors for occupational health and safety.

Thanks to these measures, the company maintains a high level of control and continuously improves its occupational health and safety management system.

Occupational Health, Industrial Safety and Environmental Protection Management System of Samruk-Energy JSC

Risk assessment and occupational health and safety performance

The introduction of the Risk Assessment Standard and the creation of the Consolidated Risk Register reflect a key principle of the occupational health and safety management system and corporate risk management. The standard provides procedures for identifying and assessing risks affecting the life and health of employees.

Risk Assessment Algorithm:

- Identification of sources of hazards;

- Selection of experts to the risk identification and assessment commission;

- Approval of the sources of hazards and the composition of the commission;

- Carrying out risk identification and assessment;

- Harmonisation of the risk assessment carried out;

- Development of measures to reduce unacceptable and control acceptable levels of risk;

- Harmonisation of the measures developed;

- Approval of the risk passport.

Employees can report incidents through official channels or to their manager. All incidents are investigated and appropriate action is taken.

Samruk-Energy JSC develops safety culture and improves employees' competence in risk management. Employees can suspend work when labour protection and safety violations are detected. In addition to this, we encourage personal initiatives of employees aimed at improving safety within the framework of specially designed motivation programmes. In the reporting period, 1,303 employees were rewarded for active participation in the safety programme.

In order to monitor compliance with the standards and detect violations in a timely manner, we actively conduct scheduled and unscheduled inspections. In the reporting period, 13 planned and 2 unplanned audits were conducted, during which 1,024 violations were identified. 29,333 internal audits were conducted at subsidiaries and affiliates, and 51,348 noncompliances were identified, of which 50,356 were eliminated. 51 audits of state authorities revealed 452 violations, for which corrective actions were developed.

List of hazard identification, risk assessment and accident investigation activities

| Indicator | 2022 | 2023 | 2024 |

|---|---|---|---|

| Number of stoppages of unsafely performed work | 92 | 22 | 52 |

| Number of fire prevention drills conducted | 650 | 485 | 512 |

| Number of exercises involving public services | 9 | 36 | 56 |

| Number of training alarms under the emergency response plan | 30 | 36 | 64 |

| Number of PABs/PNBs/PDPs conducted by PC management | 3,911 | 2,983 | 2,765 |

| Number of conducted internal audits on industrial safety | 1,338 | 21,326 | 29,333 |

| Number of identified non-conformities during internal audit | 6,031 | 52,392 | 51,348 |

| Number of inspections by state authorities | 39 | 32 | 51 |

| Number of non-compliances eliminated by state authorities | 387 | 452 | 247 |

| Amount of fines paid by state authorities, KZT million | 1.55 | 7.07 | 9.97 |

Accident investigation

To enhance safety in the workplace, the company also investigates all incidents, accidents and incidents in accordance with established procedures. In the case of incapacitating accidents, we promptly inform government authorities. In case of serious incidents with severe consequences, including fatalities, a special investigation is carried out with the participation of a state labour inspector.

To analyse the causes of incidents in depth, we apply the “Cause Tree” and “5 Why” methods, which allows us to identify root causes and develop more effective remedial actions. The results of investigations are discussed at quarterly meetings with managers and then disseminated to all subsidiaries and affiliates in the form of information reports.

The Company has implemented strict standards and procedures for incident investigation, which include risk assessment, hazard identification and development of corrective measures. In addition, the Risk Register takes into account emergencies and accidents with a high potential for serious consequences. All these measures are aimed at creating a safe working environment, eliminating hazards and actively working to prevent potential incidents.

Key activities in the field of occupational health and industrial safety

- Monitoring of personnel employment under hazardous exposure conditions (including workplace certification and industrial control);

- Control over the provision of personal and collective protection equipment;

- Providing methodological and information support to subsidiaries and affiliates;

- Monitoring of a transparent system for registering industrial accidents;

- Control of the system of individual employee responsibility (e.g. safety coupons);

- Conducting leadership behavioural safety audits;

- Identification of hazards and assessment of the significance of risks;

- Develop mechanisms to reward staff for reporting potentially dangerous incidents;

- Conducting internal accident investigations to identify root (systemic) causes;

- Record and investigate potentially dangerous incidents that did not result in accidents;

- Holding seminars and meetings at production facilities with the participation of specialists supervising labour safety issues in the Company's subsidiaries and affiliates;

- Supervise the training of first managers and labour protection specialists on IOSH, NEBOSH courses;

- Development of the concept of a unified automated system for recording incidents and violations;

- Holding competitions in the field of occupational health and safety among all the Company's subsidiaries and affiliates.

Occupational injuries

We take all necessary measures to ensure safety and minimise workplace injuries. The Safe Production system, accessible via mobile apps or PCs, provides employees with information about potential hazards and incidents. In 2024, we achieved a number of important steps in improving workplace safety and continued to actively work to improve the working environment for our employees. Despite the measures taken, tragic incidents unfortunately occurred at our facilities during the reporting period, resulting in the deaths of 3 full-time and 1 part-time employee. The main causes: personal and gross negligence of the injured person; unsatisfactory work organisation. The main measures taken: familiarisation of all the personnel of the enterprise with the causes and circumstances of the accident, conducting unscheduled briefings on the observance of safety techniques, etc. These events became an important stimulus for a deep understanding of the causes and circumstances of the accident. These events became an important incentive for in-depth analysis and development of specific measures aimed at eliminating the root causes.

In response to the incident, we have implemented improved procedures to manage HSE and improve our safety culture. We are confident that these changes will help prevent similar incidents in the future and make our processes even safer.

In addition, as part of our commitment to continuous improvement of safety standards, thorough investigations were conducted into each case. We carefully analysed the circumstances of the incidents, leading to specific findings and recommendations to prevent similar events in the future. During the investigations, 52 corrective measures were developed to prevent the recurrence of similar incidents in the future. These measures cover improving equipment reliability, improving personnel qualifications and optimising the organisation of the work process.

This approach allows us to respond quickly to incidents, implement corrective actions and develop strategic improvements based on the results of investigations. This integrated approach to risk and security management strengthens our ability to provide a high level of protection at all levels of our organisation.

Frequency of industrial injuries among the personnel of Samruk-Energy JSC

| Indicator | 2022 | 2023 | 2024 |

|---|---|---|---|

| Total number of fatal accidents | 4 | 2 | 3 |

| Frequency rate of accidents with fatalities | 0.13 | 0.07 | 0.09 |

| Total number of occupational injuries with severe consequences (excluding fatalities) | 4 | 5 | 10 |

| Frequency rate of high-consequence occupational injuries (excluding fatalities) | 0.13 | 0.16 | 0.31 |

| Total number of recorded occupational injuries | 10 | 10 | 32 |

| Frequency rate of occupational injuries (1 million hours worked) | 0.36 | 0.33 | 0.99 |

Frequency of occupational injuries among contractor organisations

| Indicator | 2022 | 2023 | 2024 |

|---|---|---|---|

| Total number of fatal accidents | 1 | 1 | 1 |

| Total number of occupational injuries with high consequences (excluding fatalities) | 2 | 1 | 1 |

| Total number of recorded occupational injuries | 3 | 2 | 3 |

Types of injuries among the personnel of Samruk-Energy JSC

| Name of injury | 2022 | 2023 | 2024 |

|---|---|---|---|

| Chemical burns, thermal burns | 1 | 2 | 2 |

| Contusion | 2 | 0 | 20 |

| Traumatic amputation | 0 | 0 | 2 |

| Electrical injuries (thermal burns) | 1 | 1 | - |

| Fractures | 1 | - | 2 |

| Complex trauma (fracture, contusion, rupture of internal organs) | 3 | 5 | 3 |

| Eye injury | 1 | 1 | - |

| Craniocerebral trauma, concussion, cerebrum | 1 | 1 | 3 |

| Total | 10 | 10 | 32 |

Measures to prevent occupational injuries:

- Informing all employees of the circumstances and causes of accidents to raise awareness and prevent recurrence;

- Conducting unscheduled briefings for all production personnel to update safety knowledge;

- Regular unscheduled knowledge checks for employees on technical operation rules, safety rules, and occupational health and safety instructions, especially in units where an accident occurred;

- Monthly “Safety Days” organised with the participation of the first managers of the enterprises, with the development of measures to eliminate the identified violations;

- Comprehensive inspections of equipment, buildings, facilities and workplaces by occupational health and safety services, with the development of specific action plans, deadlines and assignment of responsible persons;

- Training of all production personnel in accordance with established standards, including briefings and knowledge checks on industrial safety and labour protection issues;

- Holding seminars and meetings with engineering and technical personnel prior to the start of repair campaigns, including practical training on the proper authorisation of crews to carry out work and drawing up the necessary work orders;

- Carrying out certification of workplaces in terms of working conditions, at least once every five years, with mandatory adjustment of work processes and conditions;

- Replacing obsolete equipment that has exhausted its useful life and poses a hazard to workers;

- Active engagement of senior management through leadership behavioural safety audits, to build a safety culture at all levels;

- Continuous updating of the workplace hazard map/risk register to include additional training and education on hazard identification and risk assessment.

Health protection

At the enterprises of Samruk-Energy JSC, the main risk factors for occupational diseases are dust level, noise and vibration exposure. Parameters of these factors are regularly measured and controlled at workplaces.

In the reporting period, laboratory tests and certification of workplaces were carried out to identify potential harmful or hazardous working conditions. In addition, continuous industrial control is carried out at workplaces.

The Company's subsidiaries and affiliates have 48 permanent medicals, and medical personnel are also employed on a contractual basis. Every year, subsidiaries and affiliates and the Corporate Centre conclude contracts to insure employees against accidents that occur in the course of employment on the basis of tender procedures.

The costs of health protection and disease prevention measures for personnel, in accordance with legal requirements, are approved annually in the Company's development plan.

Indicators of health and occupational diseases of employees Samruk-Energy JSC

| Indicator | 2022 | 2023 | 2024 |

|---|---|---|---|

| Number of cases of health deterioration at the workplace, not related to labour activity and not resulting in fatal outcome | 18 | 10 | 4 |

| Number of deaths not related to labour activity due to health deterioration | 1 | 7 | 3 |

| Number of employees on the "D" register | 2,060 | 858 | 738 |

| Number of registered occupational diseases | 0 | 0 | 0 |

| Number of employees subject to mandatory periodic medical examination | 14,679 | 15,077 | 16,556 |

| Number of employees who have undergone periodic medical examination in accordance with the legislation of the Republic of Kazakhstan | 13,877 | 14,878 | 15,228 |

Regular medical examinations are an important part of employee health control. In 2024, 15,228 employees underwent mandatory periodic medical examinations. Based on these examinations, employees with chronic diseases receive timely treatment and rehabilitation. Employees with labour restrictions are provided with necessary recommendations and restrictions.

Employees engaged in harmful work are provided with enhanced nutrition (milk or its analogues), as well as health resort treatment as part of the corporate health improvement programme. An individual health improvement plan is developed based on medical examinations:

- dispensary monitoring of employees with chronic diseases for timely treatment and rehabilitation;

- sanatorium-resort treatment of employees with chronic diseases on the recommendation of the medical commission;

- refer workers with no occupational aptitude for further examination, followed by restrictions on working conditions.

In addition, all employees engaged in hazardous work undergo pre-shift and post-shift medical examinations. Ongoing preventive measures are taken to maintain the health of employees and prevent the negative impact of work activities on their health.

Interaction with suppliers and contractors

We recognise the importance of involving contractors in health and safety processes and integrating them into the HSE management system to ensure a high level of safety at all stages of operations.

The key document in this area is the Regulations on the Organisation of Contractors' Work on the Company's premises, which sets out the basic requirements for contractors' occupational health and safety management systems. In accordance with this document, we conduct occupational health and safety audits for both potential and existing contractors to identify the causes of incidents and accidents and assess the organisation of workplaces.

The Occupational Health and Safety Management System covers 100% of the personnel of contractors working at Samruk-Energy JSC enterprises. The Company establishes specific requirements and conditions for its suppliers and contractors aimed at compliance with industrial safety standards and respect for workers' rights, which contributes to maintaining a high level of safety at all facilities.

All contractors are subject to a system of penalties for violations of industrial safety and labour protection rules. The list of such penalties, including termination of cooperation, is detailed in the contract with contractors.

During the reporting period, 505 internal audits of contractors' activities were conducted to ensure compliance with OHS requirements. As a result, 1,058 violations were identified, which confirms the importance of continuous monitoring and auditing to maintain a high level of safety at all stages of operations.

Personnel training and competence development

We are actively working to improve the competence of our staff in the area of occupational health and safety. Occupational health and safety training is available to all employees, regardless of their position. Training programmes are developed in accordance with the requirements of legislation and adapted to specific professions, including both group and individual forms of training.

All production personnel have received health and safety training, which is a prerequisite for maintaining high safety standards at all levels of operation.

Employees of Samruk-Energy JSC are trained in the following areas:

- Behavioural safety audits;

- Occupational Health and Safety;

- Fire Safety;

- Provision of first aid;

- Safe Driving;

- Safety basics for working at height;

- Safe Work Culture;

- Other professional programmes.

All personnel undergoes compulsory training under the OHS (Occupational Health and Safety) programme in their profession and related specialties with the issuance of certificates, or by the company's training centres.

We are actively working to raise staff awareness of health and safety issues. Specialised briefings, information stands, production councils, safety leaflets and orders are used for this purpose. Information about hazards and possible situations is transmitted through the Safe Production automated system, which allows us to promptly inform employees and improve safety culture at workplaces.

Training of employees in the field of industrial safety

| Training | 2022 | 2023 | 2024 |

|---|---|---|---|

| Number of employees trained in occupational safety within the framework of the requirements of the RK legislation | 22,344 | 12,449 | 23,874 |

|

7,523 | 1,825 | 4,058 |

|

12,291 | 5,459 | 9,664 |

|

4,535 | 3,458 | 5,232 |

|

4,237 | 1,904 | 4,920 |

| Number of employees trained in the field of occupational safety beyond the requirements of the RK legislation | 236 | 244 | 12,350 |

|

82 | 102 | 12,350 |

|

0 | 0 | 0 |

|

0 | 0 | 0 |

|

294 | 316 | 0 |

| Number of employees trained to provide first aid to victims (paramedics) at the workplace | 73 | 213 | 410 |

| Number of employees trained under the NEBOSH programme | 7 | 13 | 15 |

| Number of employees trained in the IOSH programme | 4 | 102 | 55 |

| Number of employees trained in defensive driving course | 25 | 11 | 117 |

Ensuring fire safety

We provide all enterprises within the Group of companies of Samruk-Energy JSC with basic fire extinguishing equipment, including portable and mobile fire extinguishers, as well as equipment for fire water supply, such as fire hydrants. In addition, these enterprises have boxes with powder composition (sand) and fire-resistant materials such as coshma, felt and others.

Representatives of Samruk-Energy JSC, state control authorities and labour protection specialists at all enterprises of the Company conduct scheduled and unscheduled inspections to ensure availability of serviceable fire extinguishing equipment.

We actively invest in the training of our employees and organise training and drills on fire and fire prevention. In 2024, our internal formations organised 355 exercises in this area. We also organised 8 exercises with the involvement of state firefighting services.

Plans for 2025 and the medium term

In 2025, we will continue to implement measures aimed at improving the efficiency of health and safety activities, with a focus on continuous improvement of the corporate management system and its processes. Priority areas include:

- Training of production personnel on the course Culture of Safe Labour and international standards in the field of Biosafety;

- Involvement of frontline managers in Biosafety issues through leadership behavioural safety audits;

- Development and implementation of digital solutions in safety management processes, including digitalisation of HS processes;

- Launch of a project with artificial intelligence “Video Analytic” to improve risk control and prevention;

- Implementation of the Action Plan for the Year of Safety;

- Increased number of camera helmets and video badges to improve safety;

- Conducting psychological trainings for employees of subsidiaries and affiliates with the participation of qualified specialists;

- Organising and holding a preventive campaign “In the Rhythm of a Healthy Heart”;

- Holding meetings with heads of structural divisions and contractor organisations to discuss topical health and safety issues.