Caring for our planet

Management approach

Samruk-Energy JSC, as the leading energy company in Kazakhstan, pays priority attention to environmental safety issues. We are guided by national legislation, ISO 14001 international standard and best practices of sustainable development, striving to minimise environmental impact.

The Company works in the field of environmental protection in the following main areas:

- preventing and reducing environmental impacts, including improved air quality, responsible waste management and water management;

- contribution to the fight against climate change;

- conservation and rational use of energy resources;

- effective environmental monitoring and environmental impact assessment;

- conservation of landscapes and biodiversity.

To effectively control and manage environmental aspects, the Company has approved key documents:

- Corporate governance system policy;

- Corporate Environmental Protection Management Standard in the Group of companies of Samruk- Energy JSC;

- Guide to emergency environmental situations and response to them;

- Environmental Safety Programme of the Group of companies of Samruk-Energy JSC.

Environmental safety is integrated into all levels of the Company's corporate governance. Senior management is responsible for compliance with the Company's environmental commitments, targets and performance indicators. The Board of Directors approves the environmental strategy and policies.

The Energy Efficiency, Innovative Development and Environmental Safety Department of Samruk-Energy JSC assumes the role of a responsible person in managing environmental initiatives. Departments responsible for the implementation of the environmental policy and strategy, as well as for maintaining compliance of partners' and contractors' actions with the Company's established environmental standards, have been formed in subsidiaries and affiliates.

A Production Programme is developed each year, setting out key strategic objectives including:

- Raising environmental standards;

- Improvement of the quality management system;

- Optimisation of energy management;

- Improvement of working conditions and safety;

- Strengthening anti-corruption initiatives.

As part of its comprehensive environmental safety strategy, the Company has implemented an Environmental Management System (EMS). The EMS is regularly assessed for compliance with global standards with the help of independent international experts and is continuously improved. As part of the EMS, an Environmental Emergency Response Manual has been developed that defines procedures, response measures, and the organisation of on-site emergency response teams, which is updated after natural disasters and improved in line with modern and effective practices.

In the context of sustainable development and environmental responsibility, Samruk-Energy JSC systematically monitors key environmental indicators, such as the intensity of greenhouse gas and pollutant emissions, water intake and waste generation. In the reporting year 2024, the Group of companies demonstrated positive dynamics in reducing specific environmental impacts relative to economic performance indicators.

Dynamics of specific indicators of carbon intensity, pollutant emission intensity, water intake and waste generation of the Samruk-Energy JSC Group of companies (relative to income)

| Indicator | 2021 (fact) |

2022 (fact) |

2023 (fact) |

2024 (fact) |

|---|---|---|---|---|

| GHG emissions, million tonnes CO₂eq | 40.323 | 33.007 | 33.021 | 32.020 |

| Direct GHG emissions, million tonnes CO₂eq (Scope 1) | 40.308 | 32.993 | 33.010 | 32.007 |

| Indirect GHG emissions, million tonnes CO₂eq (Scope 2) | 0.015 | 0.013 | 0.011 | 0.014 |

| Pollutant emissions, tonnes | 362,647.6 | 358,079.0 | 354,922.3 | 345,373.0 |

| Total volume of water withdrawn, million m³ | 63,842.0 | 63,520.8 | 63,686.2 | 80,188.8 |

| Waste generated, thousand tonnes | 88,839.7 | 89,928.9 | 98,498.1 | 108,784.9 |

| Income from sales of products and services, KZT million | 332,537 | 381,465 | 444,960 | 573,490 |

| Carbon intensity, tonnes CO₂eq/tonne KZT | 0.121 | 0.087 | 0.074 | 0.056 |

| Average value of carbon intensity for 3 years, tonnes CO₂eq/’000 KZT | 0.094 | |||

| Dynamics relative to the average value 2021–2023, % | -41 | |||

| Deviation from 2021, % | -29 | -39 | -54 | |

| Intensity of pollutant emissions, kg/’000 KZT | 1.091 | 0.939 | 0.798 | 0.602 |

| Average value of intensity of pollutant emissions for 3 years, kg/’000 KZT | 0.092 | |||

| Dynamics relative to the average value 2021–2023, % | -36 | |||

| Deviation from 2021, % | -14 | -27 | -45 | |

| Water withdrawal intensity, m³/KZT | 0.192 | 0.167 | 0.143 | 0.140 |

| Average value of water withdrawal intensity over 3 years, m³/KZT | 0.167 | |||

| Dynamics relative to the average value 2021–2023, % | -16 | |||

| Deviation from 2021, % | -13 | -25 | -27 | |

| Waste generation intensity, tonnes/’000 KZT | 0.267 | 0.236 | 0.221 | 0.190 |

| Average value of waste generation intensity for 3 years, tonnes/’000 KZT | 0.241 | |||

| Dynamics relative to the average value 2021–2023, % | -21 | |||

| Deviation from 2021, % | -12 | -17 | -29 |

Environmental Safety Programme of the Samruk-Energy JSC Group of companies

To implement the key strategic goals of the Company for the period until 2033, in 2024 the Board of Directors approved the Environmental Safety Programme of the Company's Group of companies. This Programme is the main tool for planning the Group's environmental activities, defining goals and measures aimed at achieving environmental sustainability and increasing social responsibility.

The Programme is of a long-term target nature and serves as a basis for inclusion of the activities envisaged by it in the Group's long-term, medium-term and operational planning documents. The overall Programme implementation period is from 2024 to 2033. The actual results of achieving the target values for 2024 are presented in the table below.

Environmental Action Plan of the Samruk-Energy JSC Group of companies for 2024–2027

| Name of the event | Unit of measurement | 2023 (fact) |

2024 (target) |

2024 (fact) |

|---|---|---|---|---|

| Reduction of pollutant emissions | ||||

| Increase in electricity generation by RES facilities | billion kWh | 2.85 | 5.64 | 7.46 |

| Implementation of an automated system for monitoring emissions (NOx, SO₂, CO and dust) into the atmosphere | Number of businesses: % | 0 | 57 | 57 |

| Conversion of Almaty CHPPs to gas | thousand tonnes of pollutants | 49.1 | 48.6 | 46.4 |

| Improving the efficiency of electrostatic precipitators by performing repair work | % | 99.4 | 99.4 | 99.4 |

| Efficient management of water resources | ||||

| Reduction of water withdrawal per unit of production | m³/kWh | 0.67 | 0.66 | 2.02 |

| Compliance with water quality requirements, including wastewater | % | 100 | 100 | 100 |

| Repair of hydraulic ash removal systems of pipelines and pumping equipment at treatment facilities | % | 100 | 100 | 100 |

| Safe waste management | ||||

| Transfer of hazardous industrial waste to specialised organisations | Number of businesses: % | 100 | 100 | 100 |

| Recultivation of ash beaches at the waste accumulator (ash dump) | % | 100 | 100 | 50 |

| Placement of overburden into temporary internal dumps | million m³ | 21.98 | 25.1 | 28.0 |

| Realisation of dry fly ash | tonnes | 15,829 | at least 11,000 | 14,461 |

| Transfer of ash and slag waste for secondary utilisation | tonnes | 1,000 | 2,000 | 4,116 |

| Biodiversity conservation | ||||

| Participatory environmental impact assessment of new projects with local residents and communities | Number of businesses: % | 100 | 100 | 100 |

| Greening of the territory of the sanitary protection zone of the enterprise | % | 100 | 100 | 100 |

| Weekly monitoring of bird collisions with wind turbines | No. of WPPs: % | 100 | 100 | 100 |

| Weekly inspection of the riverbed for fish kills | Number of HPPs: % | 100 | 100 | 100 |

| Reproduction of fish resources (stocking) | % | 100 | 100 | 100 |

Deviations were recorded for two indicators:

Reduction of water withdrawal per unit of production (m³/kWh) – the target was not achieved due to transfer of assets of AES Ust Kamenogorsk HPP LLP and AES Shulbinsk HPP LLP into the Company's charter capital, which affected the calculation base and structure of water use.

Recultivation of ash beaches at the ash disposal area – the activity was not implemented due to protracted tender procedures at SDPP-1 to select a contractor organisation. The tender was held only in January 2025.

At the same time, taking into account the unfulfilled volume of reclamation of 30 hectares in 2024, in 2025 works on the area of 60 hectares are planned, which will allow to fulfil the obligations of the previous year in full.

At the end of 2024, out of 17 measures envisaged by the Environmental Safety Programme, target values were achieved for 15 indicators.

Precautionary Principle

Samruk-Energy JSC pays special attention to the assessment of possible consequences and environmental risks when planning and implementing projects. In accordance with corporate standards, a thorough risk analysis, including environmental impact and potential long-term consequences, is carried out for each project. Risk assessment is carried out with the involvement of qualified experts, which is in line with internal regulations on risk management of investment projects.

As part of the implementation of the environmental policy, both current and capital measures are taken to minimise environmental risks. Their effectiveness is constantly monitored and tools for assessing and managing environmental risks are improved.

To increase motivation and responsibility of employees for the implementation of measures to reduce environmental risks, environmental key performance indicators were introduced in Samruk-Energy JSC, which makes it possible to manage environmental safety more efficiently and achieve the set goals.

Monitoring and transparency

In order to maintain a high level of environmental responsibility, the Company provides detailed reports on environmental protection activities on a regular basis. Quarterly reports are submitted to the members of the Management Board and the profile Committee for Safety, Occupational Health and Environmental Protection, as well as annually to the Board of Directors of Samruk- Energy JSC – Report on Environmental Protection Activities for the Reporting Period.

In 2024, the Samruk-Energy JSC Group of Companies successfully passed an external surveillance audit confirming the compliance of its corporate management system with the requirements of international standards ISO 9001, ISO 14001, ISO 45001, ISO 50001, and ISO 37001.It should be noted that these international standards apply to the following assets (production sites) of the Company: Ekibastuz GRES‑1 named after B. Nurzhanov LLP, Ekibastuz GRES‑2 JSC, Almaty Electric Stations JSC, Moynak HPP JSC, Samruk Green Energy LLP, Alatau Zharyk Company JSC, AlmatyEnergoSbyt LLP, Shardara HPP JSC, First Wind Power Plant LLP, as well as the corporate centre of Samruk-Energy JSC.

Investments in environmental protection activities

Within the framework of implementation of the Action Plan for environmental protection management in the Samruk-Energy Group of companies for 2024, as well as the Environmental Action Plans of subsidiaries and affiliates for 2024 agreed with the authorised body in the field of environmental protection, 94% of the planned environmental protection measures were implemented. KZT 14.416 billion of the envisaged KZT 16.192 billion was utilised. The main activities aimed at reducing environmental impact and improving environmental efficiency included:

- Equipment modernisation: repair of burners of boiler units, reconstruction of electrostatic precipitators to reduce dust emissions.

- Optimisation of industrial processes: repair of the industrial circulation system (baghouse), maintenance of dust and gas purification plants.

- Systemic measures to reduce pollution: introduction of automated monitoring of pollutant emissions, dust suppression of ash beaches at the waste accumulator (ash dump).

- Rational waste management: waste recycling, overburden disposal into temporary internal dumps, which will reduce the volume of overburden in external dumps by 69.511 million tonnes.

- Water conservation and wastewater treatment: maintenance of storm and melt water collection and treatment system complexes.

- Greening and landscaping: increase the area of green spaces on the territory of enterprises.

- Improvement of equipment reliability: repair of units and adjustment of equipment operating mode in accordance with regime maps.

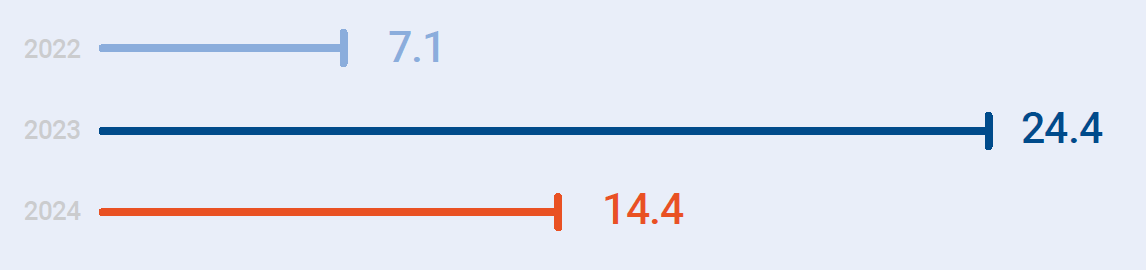

Investments of Samruk-Energy JSC in environmental protection measures, KZT billion

In 2024, Samruk-Energy JSC paid environmental tax for emissions in the amount of KZT 9.3 billion.

Compliance with environmental legislation

The Environmental Code of the Republic of Kazakhstan refers the main activities of Samruk-Energy JSC subsidiaries to the category of special nature management, which requires strict compliance with environmental standards and regulations. Each enterprise of the Company is responsible for environmental impact acting within the framework of environmental permits and norms.

We endeavour to meet all established requirements and stakeholder expectations. In accordance with the Environmental Code and the Aarhus Convention, an Environmental Impact Assessment (EIA) with mandatory public hearings in the format of open meetings is conducted before launching new projects and facilities. This process includes an information campaign to ensure transparency and consideration of public opinion.

Samruk-Energy JSC actively participates in the development of proposals to improve the Environmental Code, which contributes to the improvement of the environmental situation and financial and economic indicators of enterprises.

In 2024, authorised bodies carried out preventive inspections for compliance with environmental standards. As a result, the following violations were identified:

- Lack of automated emission monitoring systems (AEMS) at CHPP-3, CHPP-2 (AlES JSC) and EGRES-1 LLP.

- Unauthorised accumulation of construction waste on the territory of the ash dump of CHPP-3.

- Soil contamination with hazardous chemicals (fuel oil leakage at CHPP-1 due to damage to the flange connection of the fuel oil heater), which did not cause significant environmental damage.

All identified violations were promptly eliminated, additional measures were taken to prevent similar cases in the future, and control over compliance with environmental norms was strengthened at all Company facilities.

Environmental protection activities

In 2024, 94% of planned environmental protection measures, including protection of air, water and land resources, flora, fauna and biodiversity, have been implemented.

The key achievement was the introduction of an automated emission monitoring system at JSC SEGRES-2 and AlES JSC (CHPP-1 and ZTK), as well as at Bogatyr Coal LLP (for the discharge of drainage and wastewater into the Akbidayik tailings pond) with data transfer to the National Environmental Data Bank every 20 minutes in online mode.

From 1 January 2025, enterprises from the TOP-50 list are required to obtain a Comprehensive Environmental Permit (CEP), which stimulates the introduction of the best available technologies (BAT). The basis for obtaining a CEP is the BAT Reference Guide approved by the Resolution of the Government of the Republic of Kazakhstan dated 11.03.2024 No.161.

One of the prerequisites for obtaining the ERC is the development of an Environmental Performance Improvement Programme (EPIP). The Company has set a task to prepare such programmes for all subsidiaries and affiliates included in the TOP-50.

Due to the high costs of BAT implementation, EPO and KEA initiated the postponement of the implementation period. As a result, by the Resolution of the Government of the Republic of Kazakhstan dated 27.12.2024 No.1131 the deadline for implementation of BAT for energy enterprises was postponed from 2025 to 2031.

Together with subsidiaries and affiliates, preliminary measures to reduce NOx, SO₂ emissions and ash capture have been developed and will be included in the EPIP. Also, updated Roadmaps for transition to CEP were prepared and submitted to the Ministry of Energy of the Republic of Kazakhstan for approval.

17 January 2025 summarised the results of the implementation of the Environmental Action Plan for 2024 and identified further steps for subsidiaries and affiliates to comply with environmental legislation.

Within the framework of the republican environmental action “Taza Kazakstan”, during 2024 Samruk- Energy JSC implemented a number of environmental events aimed at improving environmental culture and forming a responsible attitude to the environment among employees and the population. One of the significant events was the ECO Challenge, where participants were invited to follow environmentally friendly habits in their daily lives:

- Abandon the use of plastic bags in favour of reusable eco-bags (shoppers, briefcases);

- Use your own (reusable) utensils instead of disposable crockery;

- Use paper and other resources wisely.

On a regular basis, subbotniks were held on the territory of subsidiaries and affiliates to clean up adjacent territories. As part of the ECO Challenge, the Company's young activists took part in an environmental clean-up day on the bank of the Bolshaya Almatinka River and also held a plogging event in Borovoye settlement.

In addition, within the framework of implementation of the Action Plan for Environmental Management in the Group of companies of Samruk-Energy JSC for 2024, a number of cultural, educational and environmental events were held among employees of subsidiaries and affiliates timed to celebrate World Environment Day on 5 June. The key events include:

- The employees of SEGRES-2 JSC organised an environmental action – plogging, aimed at preserving the environment and forming a careful attitude to nature;

- Environmental specialists of the production departments and specialists of the head office of AlES JSC held an environmental action “#Birge – taza taular”/“Together – clean mountains” in Butakovo gorge, as a result of which 18 bags (160 litres) of rubbish were collected;

- EGRES-1 LLP held a team building event Green Unity among the plant's employees in order to improve environmental culture and form responsibility for environmental conservation;

- Bogatyr Coal LLP organised a contest of video clips and children's drawings on the theme World Environment Day;

- Various thematic events and actions at the enterprises of AJK JSC, Shardara HPP JSC, Moynak HPP JSC, AES Ust Kamenogorsk HPP LLP, AES Shulbinsk HPP LLP and FWPP LLP aimed at popularisation of careful attitude to nature and formation of ecological thinking among employees.

Participation of Samruk-Energy team in the city‑wide clean-up day

Within the framework of the republican environmental action “Taza Kazakstan”, which was held in Astana in April 2024, the staff of Samruk-Energy JSC took an active part in the city-wide clean-up day. The main purpose of the event was to raise awareness of environmental culture and the importance of preserving the environment.

The Company's employees cleaned the Alley of Power Engineers, which was planted by Samruk-Energy JSC in honour of the 15th anniversary of the Samruk-Kazyna Fund. This event became an important contribution to improving the environmental situation in the city and once again emphasised the company's responsibility for sustainable development and care for the environment.

Open dialogue with stakeholders on environmental issues

We constantly maintain a dialogue with stakeholders on environmental protection issues. This allows us to monitor the effectiveness of decisions made and measures implemented, as well as to update environmental risks.

In 2024, the Company held public hearings on four projects, which resulted in favourable conclusions.

Guided by the principle of information transparency and accountability, Samruk-Energy JSC organises meetings, press conferences and round tables to discuss environmental issues with representatives of the public, mass media, volunteer and non-profit organisations. Top managers of the Company, as well as representatives of the management of subsidiary organisations participate in these initiatives.

In 2024, representatives of the company participated in the following activities:

- Discussion of the impact on tariffs and further amendments on return on investment for EPO as part of the dialogues with the Kazakhstan Electricity Association.

- Participation in roundtables on the issue of alternative option of financial provision for facilities of I category together with NPP Atameken and other associations.

- Development of proposals to amend the Code of Administrative Offences of the Republic of Kazakhstan with regard to exceeding technological standards for emissions and discharges. These proposals were submitted as part of the work of the joint working group on energy, environment and oil and gas industry of the Foreign Investors Council under the President of the Republic of Kazakhstan.

- Participation in the Round Table on waste management. The Chief Manager of Department of Environmental and Industrial Safety of Samruk- Energy JSC moderated the session “Sustainable Management of Industrial and Hazardous Waste: ESG Approaches”.

- Webinar organised by Samruk-Energy JSC for subsidiaries and affiliates on environmental regulation with participation of speakers discussing environmental regulation issues.

Direct appeals on environmental issues can be made through the official https://samruk-energy.kz/ru/navigation-and-support/, which allows messages to be registered in the incident management system. They are then analysed, verified and forwarded to the relevant departments for appropriate action.

Training of employees in the field of environmental protection

Samruk-Energy JSC has a Corporate Environmental Training Programme aimed at formation, development and advanced training of employees in the field of environmental protection. The purpose of the programme is to provide the necessary level of knowledge and competencies for efficient performance of environmental tasks, as well as to promote sustainable strategic development of the Company.

Training is provided at least once a year and covers a wide range of environmental topics including:

- Basic requirements of the environmental legislation of the Republic of Kazakhstan;

- Identification and management of environmental risks;

- Methods of minimising the negative impact on the environment;

- Implementation of the best available technologies;

- International sustainability standards and practices (including ISO 14001, ISO 9001, GRI, TCFD, CDP, ESG principles).

Within the framework of the Corporate Programme in 2024, an online seminar for Samruk-Energy JSC subsidiaries and affiliates was held on the topic: Innovations in the field of environmental regulation and bylaws regarding the procedure for conducting EIA and issuing environmental permits.

On 28 November, the Risk Management and Internal Control Department with the involvement of a training organisation held a corporate seminar on the topic: Climate Risks for Energy Sector Enterprises.

On 10 December 2024, McKinsey conducted training for members of the Board of Directors, top management and executives of the Company on the topic: Climate Change and Energy Outlook.

Atmospheric emissions

Management approach

We are committed to reducing atmospheric emissions and are implementing measures aimed at reducing pollutants. Particular attention is paid to minimising atmospheric pollution at enterprises such as EGRES-1 LLP, SEGRES-2 JSC, AlES JSC and Bogatyr Coal LLP, which operate on fossil fuels and have a significant impact on emissions.

The Company ensures control over compliance with the maximum permissible emission standards with mandatory reporting to supervisory authorities. Air quality is regularly monitored as part of the Industrial Environmental Control Programme to ensure compliance with environmental standards.

Actual technical and environmental performance is analysed on a quarterly basis, comparing it with norms and data from previous years. Information on possible environmental risks is provided to facility managers and senior management.

Pollutant emissions are strictly regulated by RK legislation and comply with design and regulatory documents agreed with state authorities.

Emissions monitoring includes observation of emissions at sources to track their volume and quality. Based on monitoring data, pollutants are analysed in accordance with national environmental standards.

EGRES-1 LLP, SEGRES-2 JSC, AlES JSC and Bogatyr Coal LLP measure emissions of harmful substances in flue gases, such as nitrogen oxides, sulphur dioxide and dust particles, in accordance with the Production Monitoring Schedule. Measurements are performed by accredited laboratories, and specialised software is used to calculate emissions. Based on these data, an Atmospheric Air Protection Report (Form No. 2-TP (air)) is prepared.

To minimise emissions, equipment efficiency is regularly checked and, where necessary, new technological solutions are introduced. The facilities are continuously monitored for equipment specifications affecting emissions, effluents and waste.

When planning new facilities, factors are taken into account to minimise the impact on the atmosphere. In the case of the new plants at Ekibastuz, particular attention is paid to location close to fuel sources to minimise the environmental risks of coal transport. The correct choice of chimney heights helps to better distribute emissions, taking into account topography, wind direction and distance to settlements.

Indicators of pollutant emissions

The main sources of pollutant emissions in the Company are boiler units, oil farms, fuel oil farms, ash dumps and other facilities located on the territory of fuel stations and boiler houses (EGRES-1 LLP, SEGRES-2 JSC, AlES JSC, Bogatyr Coal LLP). The key pollutants generated by fuel combustion at these enterprises are nitrogen oxides (NOx), sulphur dioxide (SO2), fuel oil ash, ash/dust, carbon monoxide (CO) and volatile organic compounds.

Calculation of pollutant emissions is carried out in accordance with the methodological documents in the field of environmental protection approved by the Order of the Minister of Environment and Water Resources of the Republic of Kazakhstan dated 12 June 2014 No. 221-Ө. The calculations take into account the main characteristics of the fuel used: lower calorific value (kCal/kg), working ash content (%), working sulphur content (%), share of ash in the fly ash (%) and its consumption in physical terms.

Pollutant emissions are monitored in accordance with subsidiaries and affiliates' Environmental Control Programmes agreed with the authorised body in the field of environmental protection.

In accordance with the requirements for the use of natural resources established in environmental emission permits, Ekibastuz SDPP-1 LLP, SEGRES-2 JSC, AlES JSC, Bogatyr Coal LLP, Shardara HPP JSC and Moynak HPP JSC developed and agreed with the authorised body in the field of environmental protection plans of environmental protection measures.

The said plans include a set of measures aimed at:

- protection of atmospheric air;

- rational use and protection of water resources;

- land conservation;

- preservation of biodiversity (flora and fauna);

- safe handling of production and consumption waste;

- ensuring radiation, biological and chemical safety;

- implementation of environmental management systems and best available technologies.

The implementation of activities within the framework of these plans is mandatory and is carried out in accordance with the established procedure.

Dynamics of specific air emissions per unit of production, g/kWh

| 2022 | 2023 | 2024 | Δ 2024/2023, % |

|---|---|---|---|

| 9.5 | 9.5 | 8.2 | -13.8 |

Based on 2024 data, specific air pollutant emissions decreased by 13.8 per cent compared to the 2023 figure.

The positive trend is due to:

- reduction of the specific consumption of conventional fuel at SEGRES-2 JSC from 381.3 g/kWh to 374.7 g/kWh.

- increase in electricity production from RES by 2.6 times, from 2.849 billion kWh to 7.460 billion kWh as a result of transfer of assets of AES Ust Kamenogorsk HPP LLP and AES Shulbinsk HPP LLP into the authorised capital of the Company.

Key activities in the field of atmospheric air protection in 2024:

- Provision of high degree of flue gas purification from ash (SiO2 content 70-20%) by repairing electrostatic precipitators;

- Development of design and estimate documentation for reconstruction of burner units to reduce nitrogen oxide emissions;

- Carrying out repairs to aspiration units used in fuel supply;

- Repair of dust collection systems on drilling machines.

Environmental control in online mode

In 2024, Samruk-Energy JSC implemented automated monitoring and control systems (AMS) for emissions into the atmospheric air at stationary emission sources of SEGRES-2 JSC, power units No. 7 and No. 8 of EGRES-1 LLP, as well as B. Orazbayev CHPP‑1 and the Western Heat Complex (WHC) of AlES JSC. These systems are an important element of the Company's Environmental Safety Programme of the Samruk-Energy JSC Group of companies.

The purpose of AMS installation is to provide control, monitoring, and incentives for enterprises to reduce their impact on the urban and natural environment. The system allows tracking emissions of such substances as nitrogen oxides (NO, NO2, NOx), sulphur dioxide (SO2) and others, as well as calculating the gross volume of these emissions.

All data are transmitted in real time to the information system of the Ministry of Ecology and Natural Resources of the Republic of Kazakhstan.

Plans for 2025 and the medium term

Study of advanced methods of flue gas cleaning at EGRES-1 LLP, SEGRES-2 JSC, AlES JSC with focus on removal of ash, dust, nitrogen oxides (NOx) and sulphur oxides (SOx).

Determination of the final cost of implementing BAT after a comprehensive analysis of available technological solutions.

Construction of clarified water return pumping station within the framework of design and estimate documentation at P stage for the project “Expansion and reconstruction of Ekibastuz GRES-2 with installation of power units No. 3,4”.

Responsible water use

Management approach

Samruk-Energy JSC works to identify and prevent possible impacts of its activities on water resources. The Company carefully controls the withdrawal and use of water resources at its production enterprises to ensure compliance with environmental standards.

Our subsidiaries, including EGRES-1 LLP, SEGRES-2 JSC, AlES JSC, Bogatyr Coal LLP, Moynak HPP JSC, Shardara HPP JSC, AES Shulbinsk HPP LLP, AES Ust Kamenogorsk HPP LLP and AZhK JSC do not operate water resources in water scarce regions, but we place great importance on sustainable water management. This includes assessing risks and implementing strategies to minimise clean water consumption and effectively treat wastewater to ensure it is safely returned to nature.

Our water resources management complies with the Water Code of the Republic of Kazakhstan and major permits, ensuring proper protection of water resources.

Basic principles in water resources management:

- Responsible water use and maintaining a sustainable water balance;

- Assessment and accounting of all water abstraction points, including water abstraction through intermediaries;

- Continuous improvement strategies to optimise the use of water resources;

- Minimising the use of potable water for industrial purposes;

- Annual revision of metering devices for water intake and wastewater disposal, checking their availability, functionality, and timely calibration and sealing by regulatory authorities;

- Excluding operations in water scarce regions, which emphasises our environmental responsibility.

We actively co-operate with local authorities to ensure access to quality drinking water. Our openness to dialogue allows us to carefully consider citizens' requests regarding the impact of our activities on local water resources.

Main sources of water resources:

- Bestiubinskoye reservoir (Moynak HPP);

- Shardara reservoir (Shardara HPP);

- Shulbinsk water reservoir (Shulbinsk HPP);

- Ust-Kamenogorsk reservoir (Ust-Kamenogorsk HPP);

- K. Satpayev Canal (Bulat Nurzhanov Ekibastuz GRES‑1 LLP, Station Ekibastuzskaya GRES-2 JSC);

- Shidertinskiy Canal (Station Ekibastuzskaya GRES‑2 JSC);

- Big Almaty Lake and the basin of the Big Almatinka River (HPP Cascade);

- Kapshagai reservoir (Kapshagai HPP).

At the enterprises of EGRES-1 LLP, SEGRES-2 JSC, AlES JSC, Bogatyr Coal LLP, Moynak HPP JSC, Shardara HPP JSC, AES Shulbinsk HPP LLP, AES Ust Kamenogorsk HPP LLP and AZhK JSC monitoring of water resources quality is regularly conducted. Accredited laboratories analyse waste water and water supply sources, identifying pollutants and ensuring a high level of environmental safety. Based on this data, an action plan is developed to optimise water management and minimise environmental impact.

Water withdrawal

EGRES-1 LLP, SEGRES-2 JSC, AlES JSC and Bogatyr Coal LLP withdraw water in volumes required for production processes, in strict compliance with design and regulatory requirements approved by the regulatory authorities. These enterprises are actively developing sustainable water management plans, including measures to reduce freshwater consumption, effectively treat wastewater, minimise water losses during transportation and improve wastewater reuse systems.

As part of our water conservation strategy, we actively utilised closed-loop water supply systems, including storage reservoir coolers and direct ash removal systems at the Ekibastuz TPPs. At the Almaty CHPPs, recirculating cooling systems with cooling towers were used, and water from ash dumps was utilised to improve water use efficiency and protect the environment.

Volume of reusable and recycled water, megalitres

| Indicator | 2022 | 2023 | 2024 | Δ2024/2023, % |

|---|---|---|---|---|

| Volume of reusable water | 7,327 | 8,328 | 8,620 | 3.5 |

| Volume of recycled water | 3,527,190 | 3,490,881 | 3,541,091 | 1.4 |

In 2024, the volume of water withdrawn by TPPs per unit of output was 6.81 m³/ thousand kWh, which is 3.1% less than in the previous year. This indicates a decrease in the water intensity of TPP production processes in the reporting period.

Water efficiency of production, m³/ thousand kWh

| Indicator | 2022 | 2023 | 2024 | Δ2024/2023, % |

|---|---|---|---|---|

| Volume of water withdrawal per unit of output | 6.30 | 7.03 | 6.81 | -3.1 |

Water discharge

We adhere to high standards of wastewater handling to minimise its negative impact on aquatic ecosystems. Samruk-Energy JSC endeavours not to exceed the established wastewater discharge limits and to comply with regulations, which allows protecting biodiversity and natural habitats.

In 2024, we conducted thorough quality control of water resources, including surface, ground and waste water, using certified laboratories, as part of the Environmental Monitoring Programme. According to the results of analyses at the facilities of EGRES-1 LLP, SEGRES-2 JSC, AlES JSC, Bogatyr Coal LLP, Moynak HPP JSC, Shardara HPP JSC, AES Shulbinsk HPP LLP, AES Ust Kamenogorsk HPP LLP and AZhK JSC did not record violations of established norms on the content of pollutants.

Water is discharged to specially designated places: rainwater is directed to river systems and accumulation ponds, and industrial wastewater for ash and slag transport – to ash dumps, excluding discharge into natural water bodies. All wastewaters, except those used for hydraulic transport of ash and slag, are treated until they reach sanitary and environmental standards established by legislation.

In the process of production and economic activity of EGRES-1 LLP, SEGRES-2 JSC, AlES JSC, Bogatyr Coal LLP, Moynak HPP JSC, Shardara HPP JSC, AES Shulbinsk HPP LLP, AES Ust Kamenogorsk HPP LLP and AJK JSC two categories of wastewater are formed:

- More than 99% of the total volume is wastewater from the hydraulic ash removal system, as well as treated water used for cooling technical units of CHPPs and water used for electricity generation at HPPs.

- Less than 1% of the total volume is domestic wastewater collected from administrative buildings, canteens and offices.

Wastewater treatment is carried out using modern physical, chemical and biological technologies. The development of standards for maximum permitted discharges is based on the methodology approved by the Ministry of Ecology, Geology and Natural Resources of the Republic of Kazakhstan in March 2021. The quality of treated wastewater is monitored by a certified laboratory, ensuring compliance with environmental standards.

Domestic wastewater is treated at the biological treatment plant Stok, which has two parallel treatment lines with a capacity of 15 m³ per day. The treatment system includes a biological treatment unit, additional filtration and a water disinfection unit, ensuring a high level of treatment before discharge into natural water bodies.

Surface water quality assessment is carried out by general and special indicators. General ones include mineralisation, pH, hardness and other parameters, while special ones include chemical and biochemical oxygen demand, content of oil products, ammonium salts, nitrates, phosphates and other pollutants.

In 2024, EGRES-1 LLP, SEGRES-2 JSC, AlES JSC, Bogatyr Coal LLP, Moynak HPP JSC, Shardara HPP JSC, AES Ust Kamenogorsk HPP LLP, AES Shulbinsk HPP LLP and AZhK JSC will be allocated 80,043,391 megalitres of wastewater for production and household and drinking needs. At the same time, 99% of the withdrawn water is used for operation of hydroelectric generators of HPPs to produce electric power. The total volume of water withdrawal was 80,188,759 megalitres in the reporting period.

Data collection process for monitoring water consumption and abstraction

| Enterprise | Data collection process |

|---|---|

| Samruk-Energy JSC | Annually, according to the reporting form, as well as in case of need for information on water use, a request is made to subsidiaries and affiliates. |

| AlES JSC | Daily data collection on water intake/consumption is carried out by requesting data by e-mail on the amount of transferred make-up water to Heating Networks LLP, water consumption from Almaty and Talgar water intakes for the needs of CHPP-1 and CHPP-2, as well as water releases in accordance with BABI instructions by fax for Kapshagay HPP and HPP Cascade. All data are displayed in the daily report – Daily report by stations of AlES JSC. Monthly reporting data collection is carried out using email with provision of water withdrawal/ consumption/discharge balance from each production unit. |

| EGRES-1 LLP and GRES-2 JSC | Detailed accounting of water consumption is maintained through an automated system, which includes daily tracking of the volume of water withdrawn from the Kanysh Satpayev Canal for domestic and drinking needs, as well as water provided to secondary users, used in ash removal systems and for other auxiliary purposes, including for industrial and firefighting needs. Data are collected and analysed by entering information into an Excel spreadsheet and keeping a log of primary water accounting, which ensures the accuracy and transparency of water resources monitoring. |

| AES Ust-Kamenogorsk HPP LLP, AES Shulbinsk HPP LLP, MGES JSC and SHHPP JSC | The use of water through the power plant turbines is subject to continuous monitoring and recording by plant operatives 24 hours a day, 7 days a week. Water consumption for domestic and potable purposes is monitored by the operator of the main pump intake. |

| Bogatyr Coal LLP | On a monthly basis, in accordance with the approved energy facilities maintenance procedures, specialists responsible for water meters transmit data from these devices for verification and drawing up an official statement of readings in co-operation with the State Utility Enterprise Gorvodokanal. Archived data on wastewater discharge recorded by the meters installed at key facilities are printed out on a monthly basis in accordance with the terms of the contract with the service company. To monitor the turnover of water resources, including consumption, abstraction and discharge of drainage water, data from water meters are recorded every day and entered into a special logbook according to the annex to the rules of primary registration of water use. |

Plans for 2025 and the medium term

As part of the 2025 Production Environmental Control Program, the Company's enterprises, with the involvement of licensed and accredited specialised laboratories, will conduct environmental monitoring to assess the impact of power plant operations on surface water in the areas where they are located.

The following types of observations are planned for monitoring of water resources in the zone of influence of the enterprise:

- Monitoring of water quality composition;

- Monitoring of the quantitative and qualitative composition of water of the cooling system of turbine condensers and water for ash and slag waste transportation to the ash dump;

- Monthly observations of impacts on water bodies, according to the monitoring schedule provided in the programme.

Groundwater quality will be monitored through a network of observation wells located along the groundwater flow direction. The wells are equipped with metal casing and are numbered in sequence..

Waste management

Management approach

Responsible waste management is an important component of Samruk-Energy JSC's environmental strategy. We strive for efficient use of resources and minimisation of waste impact on the environment at all stages of our activities, from power generation to facility operation.

The Company carries out waste management activities in accordance with the requirements of the legislation of the Republic of Kazakhstan, including keeping records of waste generated, treated, utilised, neutralised, transferred to other persons or received from other persons, as well as disposed waste. The data are summarised quarterly and annually.

Waste management is organised in strict accordance with established standards and procedures, including:

- Corporate standard for environmental protection;

- Waste Management Programmes;

- Waste Management Action Plan.

Contractors working with waste are closely monitored at the facilities. During the procurement process, contractors are checked to ensure that they have the necessary licences and that they have the appropriate logistics for safe waste management. Contractors are required to sign contracts confirming compliance with environmental regulations and legislation of the Republic of Kazakhstan. Environmental services regularly inspect their activities.

We actively engage with stakeholders by providing channels for submitting environmental comments through Samruk-Energy JSC; all appeals are recorded and thoroughly reviewed.

Waste inventory was carried out in EGRES-1 LLP, SEGRES-2 JSC, AlES JSC, Bogatyr Coal LLP, and methods of waste accumulation were developed for each type of waste, taking into account its hazard class, toxicity, physical state and other characteristics.

Hazardous waste requires specialised disposal, while non-hazardous waste is subject to separate collection and recycling. For separate collection of waste, special points and areas with containers and metal containers labelled for easy identification have been set up. Criteria for waste that cannot be buried and materials suitable for recycling have also been established.

Bogatyr Coal LLP is actively working to minimise its environmental impact by reducing the volume of overburden placed on external dumps. The Company is developing plans to adapt the mined-out areas of the Severny and Bogatyr open pits for use as internal dumps. To prevent oxidation and spontaneous combustion of carbon-containing rocks, inert materials are used to isolate and compact the surface layer of the dumps.

Development of HPPs and RES facilities in Samruk- Energy JSC contributes to the reduction of ash and slag waste per unit of output.

Waste management indicators

The companies organise the collection of used batteries containing toxic substances such as lead, mercury and cadmium, which can be harmful to health and the environment. Used batteries are sent for recycling to avoid them ending up in landfills. From 2020 to 2024, 285kg of batteries were collected and sent for recycling.

In the course of their operations, EGRES-1 LLP, SEGRES-2 JSC, AlES JSC and Bogatyr Coal LLP do not generate radioactive waste. Radiation monitoring is conducted every quarter and the results show that radiation levels remain within the safe standard of 2.5 μSv/hour, confirming the effectiveness of existing radiation safety measures.

In 2024, 108.784 million tonnes of waste were generated, which meets environmental requirements. The main wastes are overburden and ash and slag waste. The volume of waste increased by 10% compared to 2023 due to the acquisition of an excavator and dump trucks by Bogatyr Coal LLP, as well as the engagement of a contractor to perform stripping works. These measures allowed to increase the volume of stripping works from 2.344 million m³ to 8.364 million m³ in 2024.

At the same time, the volume of ash and slag waste decreased by 0.8% due to a decrease in electricity generation at GRES-1 and Almaty CHPP-2, as well as a decrease in specific fuel consumption at GRES-2.

Total waste volume of Samruk-Energy JSC enterprises, tonnes

| Показатель | 2022 | 2023 | 2024 | Δ 2024/2023, % |

|---|---|---|---|---|

| Всего образовано отходов, из них | 89 929 927 | 98 496 096 | 108 784 900 | 10,4 |

| Опасных | 647 | 1 732 | 534 | -69,2 |

| Неопасных | 89 928 281 | 98 496 364 | 108 784 366 | 10,4 |

| Из них по основным видам отходов, характерным для специфики производства | 89 912 725 | 98 474 212 | 108 760 267 | 10,4 |

| Золошлаковые отходы | 7 129 158 | 8 853 230 | 8 781 174 | -0,8 |

| Вскрышные породы | 82 783 567 | 89 620 982 | 99 979 093 | 11,6 |

Plans for 2025 and the medium term

- Development and implementation of measures aimed at minimising the impact of waste on the environment and employee health.

- Monthly records of waste generation, delivery, recovery and disposal.

- Transferring waste to third party organisations for recycling or disposal.

- Development of technologies for effective ash and slag waste management using dust suppression.

- Compliance with norms for temporary storage of waste (not more than 6 months) before its further disposal or recycling.

Biodiversity conservation

Management approach

We care about biodiversity conservation and monitor the effectiveness of biodiversity mitigation measures. We do not operate in protected areas or areas of high biodiversity value.

We have implemented a Corporate Environmental Management Standard, which is the basis for our commitment to implementing measures to protect nature. This standard aims to prevent or minimise the impact of our operations on biodiversity and includes strategies to conserve nature, manage environmental risks and aspects affecting biodiversity.

Key areas for maintaining and protecting biodiversity:

- Introduction of advanced technologies that reduce the environmental impact on the environment during the production process.

- Development and implementation of programmes to protect and conserve biodiversity in areas adjacent to production zones.

- Regular monitoring of environmental conditions in order to promptly identify and eliminate threats to ecosystems.

In accordance with the environmental legislation of the Republic of Kazakhstan, when expanding or modernising its operations, the Company analyses the possible impact on the ecological system and biodiversity of the region where our production facilities are located.

Results of biodiversity protection activities

We actively work to protect and enhance natural ecosystems at all stages of our operations, from power generation to decommissioning.

As part of this work, wildlife conservation projects are being implemented, co-operation is being established with scientific and research institutes, as well as with government agencies. One example of cooperation with international environmental organisations is the project of Moynak HPP JSC to preserve a relic ash grove on the Charyn River, implemented with UNDP experts in Kazakhstan.

In accordance with the 2024 Environmental Protection Action Plan of the Samruk-Energy JSC Group of companies, plans for monitoring the impact of economic activities on fauna and flora were developed and approved in Shardara HPP JSC, Moynak HPP JSC, AES Ust Kamenogorsk HPP LLP, AES Shulbinsk HPP LLP, AZhK JSC and FWPP LLP.

As part of the implementation of these plans, the following activities have been carried out in 2024:

- visual inspection of water surface of Bestiubinsk, Shardara, Ust-Kamenogorsk and Shulbinsk reservoirs for possible fish kill;

- conducting environmental briefings to improve the environmental culture of the personnel;

- planting of spruce and elm saplings;

- stocking of water bodies with fish;

- visual inspection of power line routes and territories of wind power plant areas to detect bird deaths.

All planned activities on biodiversity conservation in 2024 were implemented in full. No cases of fish and bird mortality were recorded in the reporting period. The Shulbinskoye Reservoir and the Irtysh River were stocked, spruce and elm seedlings were planted, environmental awareness was organised for employees of subsidiaries and affiliates, and thematic environmental bulletins were published.

Two bird species listed in the Red Book of Kazakhstan have been recorded in the area of the 45 MW HPP near the town of Ereimentau (FWPP LLP): the Imperial Eagle and the Steppe Eagle42. The birds inhabit valleys and along roads, but at a distance from the turbine sites. The assessment showed that the risk of bird collisions with wind turbines is minimal. No incidents with migrating birds have been recorded during the operation of the wind farm, as confirmed by records in the logbook.

42 As per the Final Report of the zoological survey dated 07.10.2013.

Our sites are located in Pavlodar and Almaty regions characterised by a high level of anthropogenic impact. They are located in industrial areas that are not home to flora and fauna species listed in the Red Book or endangered species. We strive to minimise our ecological footprint and constantly monitor the impact on the natural environment.

We actively support biodiversity by implementing programmes aimed at protecting flora and fauna. Our efforts in this area contribute to the fulfilment of the UN Sustainable Development Goals No. 14 and No. 15, which underlines our commitment to responsible business and environmental protection.

In 2024, the Company's subsidiaries and affiliates invested KZT 224.1 million in the improvement and landscaping of the sanitary protection zone, which is 95.4% higher than the previous year's investments.

Investments in biodiversity conservation, million KZT

| 2022 | 2023 | 2024 | Δ 2024/2023, % |

|---|---|---|---|

| 57.9 | 114.7 | 224.1 | 95.4 |

In order to protect fish populations at our Company's hydroelectric power plants, specialised fish protection systems have been installed on hydro turbines. In accordance with the recommendations of the Kazakh Research Institute of Fisheries, a measure has been implemented to protect spawning fish: illumination of the water surface with floodlights at night near water intakes in front of turbine conduits. This effectively discourages fish and minimises their ingress into the turbines, contributing to the preservation of the ecosystem.

To protect birds that use overhead power line poles as resting places, AZhK JSC implements projects to reconstruct poles with the installation of insulated wires and special ruffles that prevent birds from landing on the traverses. These measures significantly reduce the risk of electrical contact damage, contributing to the safety of birds and the conservation of their populations.

The operating regimes of our hydropower plants are coordinated with the Ministry of Water Resources, local authorities and the management of specially protected natural areas, especially in the area of Moynak HPP. Regulation of water flows for agriculture and water supply is carried out in close cooperation with authorised bodies to balance interests and protect ecosystems.

During the pre-design and design phase of the wind turbine, special attention is paid to minimising the impact on nature. For example, in order to minimise light pollution that could disturb the biorhythms of flora and fauna, lighting on the wind turbine is limited to the required position lights, which contributes to the maintenance and restoration of biodiversity.

Restoration of fish population in the Irtysh River

Ust-Kamenogorsk and Shulbinsk HPPs continue to contribute to the preservation of the ecological balance of the region by regularly implementing measures to reproduce aquatic bioresources. In 2024, 130,111 young carp were released into the Irtysh River as part of the environmental action. The choice of location for the release of fish was carefully coordinated with a scientific organisation, which made it possible to determine the optimal location for this process – the village of Azovoye, located along the bed of the Irtysh River. This section of the reservoir was not chosen by chance: its natural conditions are favourable for the habitat and reproduction of young fish, which in turn contributes to the strengthening of the population of these fish species.

Such ecological actions have a positive impact on maintaining the fish balance in the water body and contribute to the preservation of the ecosystem of the region as a whole.

Land reclamation

We are rigorous in our commitment to land reclamation, which significantly reduces negative environmental impacts while maximising environmental and social benefits. To ensure the sustainability of the closure and rehabilitation of waste pits, we allocate significant resources to cover all associated costs.

A key element of reclamation is the active participation of local communities, which increases the transparency of our actions and takes into account the interests of residents. This co-operation helps us better understand community needs and provides the basis for developing effective ecosystem restoration plans.

We pay special attention to the development and implementation of measures aimed at reducing the impact of our activities on the natural environment. In this context, special attention is paid not only to restoring the ecological value of reclaimed areas, but also to supporting biodiversity and protecting unique ecosystems.

Elimination of ash dumps

Under the Environmental Code, we have a legal obligation to dispose of ash dumps, which are specialised areas for the disposal of waste generated by our operations.

In 2024, the estimated value of the fund for the liquidation of ash dumps totalled KZT 3,739.3 million, which is 18.96% higher than in the previous year. This increase is due to an increase in the cost of works and materials for reclamation.

Carrying amount of reserve for ash dumps liquidation, KZT million

| 2023 | 2024 | Δ 2024/2023, % |

|---|---|---|

| 3,143.4 | 3,739.3 | 18.96 |

The assessment of the current reserve for ash disposal site remediation is based on the current environmental legislation of the Republic of Kazakhstan and is supported by feasibility calculations and engineering studies that comply with current reclamation standards and methodologies. The estimate may be adjusted depending on the results of future environmental studies and updates to reclamation and remediation programmes.

Plans for 2025 and the medium term

- Greening the territory and increasing the area of green spaces;

- Regular laboratory tests as part of industrial environmental control to monitor and assess the environmental impact of the Company's operations;

- Recultivation of worked-out areas of ash dumps, including their restoration and transformation into ecologically safe and functional zones.